Your Cart is Empty

-

- #MadeEasy

- Calendars

-

Wall Calendars

- Patriotic Wall Calendars

- American Scenic Wall Calendars

- Canadian Scenic Wall Calendars

- World Scenic Wall Calendars

- Cars, Trucks And Bikes Wall Calendars

- Wildlife Wall Calendars

- Art Wall Calendars

- Inspirational & Motivational Wall Calendars

- Food & Beverage Wall Calendars

- Health & Wellness Wall Calendars

- Home And Gardens

- Desk Calendars

- Magnet Calendars

-

- Writing Tools

- Headwear

- Drinkware

- Clearance

-

- Home

- Blog

- Making Promo Easy

- Imprint Methods: Laser Engraving

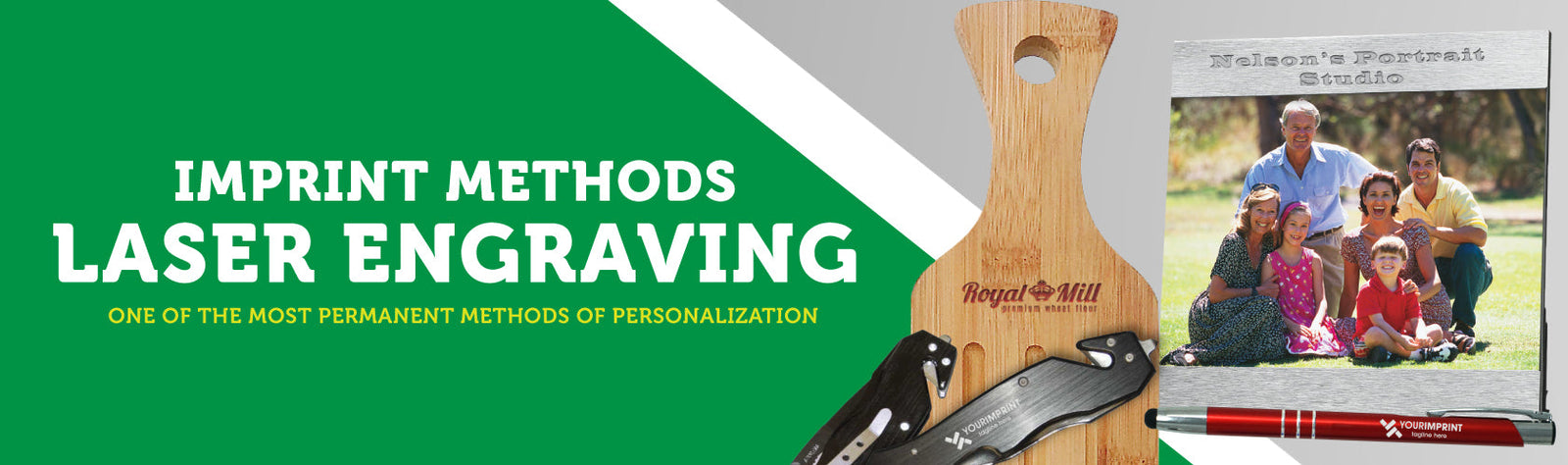

Imprint Methods: Laser Engraving

Posted on August 05, 2022 Posted in Making Promo Easy

One of the Most Permanent Methods of Personalization

A good understanding of the different ways promotional items can be personalized can help you to make an informed decision about what products and customization styles are best suited to your needs.

In this behind-the-scenes blog, we’re taking a brief glimpse at the world of laser engraving. Engraving is one of the oldest methods of personalizing items, with the earliest known engraving dating back to half a million years ago.

Traditionally, engraving was done manually by carving grooves into objects with the use of other hard objects. Today, with the help of computer programs and powerful lasers, we can engrave almost any hard material quickly and cleanly.

How does laser engraving work?

In simplest terms, lasers are created by concentrating light repeatedly, resulting in the creation of a powerful beam, or laser. There is, of course, much more to lasers than that, but for the sake of simplicity, we won’t dive too much further into the composition of lasers themselves.

Instead, let’s focus on what makes lasers the perfect tool for engraving. Lasers can contain very high amounts of compacted energy, which can burn through almost any kind of material. Laser machines produce engravings on wood, glass, metals, and much more by focusing laser beams at the right intensity and distance from a material to burn away the top layer of the surface, resulting in an engraved design. It is imperative to use the right laser intensity at the right distance for each unique type of material. If these measurements are miscalculated, you risk burning right through the object or leaving no mark at all.

The laser engraving process generally involves uploading a design onto computer software, which then tells the laser what to do. The object is mounted into the laser machine at the correct distance and orientation, and the intensity of the laser is set depending on the type of material being engraved. Softer materials like wood and gold will require a lower-powered laser, while hard materials such as steel require a stronger laser.

Some laser machines work by moving back and forth in lines over the surface of the object, similar to the way our office printers work. This style of engraving is best suited for large designs. Other lasers are stationary, and it is the object itself that is moved, and others rely on mirrors to redirect the laser beam while both the laser and the surface material remain stationary. There are also unique laser machines that are designed to create engravings on cylindrical surfaces.

Benefits of Laser Engraving

Engraving is one of the most permanent methods of personalization on an object. Of course, some softer materials may erode over time, and the surface of items can generally be shaved down if one wants to get rid of an engraving. But if you are looking to personalize something in a way that will withstand the test of time, dirt, washing, and general wear-and-tear, engraving may be the perfect solution.

Engravings also carry with them a sense of elegance and class. People tend to have important and valuable items engraved, and engraving is generally regarded as a ‘fancy’ way to personalize an item. If your goal is to elevate your brand with a high-class look, you may also want to consider investing in engraved promotional items.

We hope you enjoyed this very basic tour through the world of laser engraving, and we hope that you learned something useful along the way! If you liked this article, you can also check out our behind-the-scenes blogs on DTG Printing, embroidery, and screenprinting. And follow Facebook, Instagram, Twitter, and our blog for more behind-the-scenes content!

promo products made easy.